We are really excited to announce our commitment to sustainability through the development of a mini conical single-screw extruder for recycled materials. In a world increasingly focused on eco-conscious solutions, we are excited to join the global trend towards recycled materials. Our mini conical extruder and conical screw 16 mm, compatible with various downstream units such as blown film, cast film, filament extrusion, pelletizing lines and our new COMBI lines, offer versatility and efficiency in recycling processes. While our current focus is on the mini extrusion line, Labtech Engineering also offers single conical extruders for our larger standard lines. Join us in shaping a brighter and more sustainable future.

This mini conical extruder presents an optimal solution for processing small-scale samples, making it an ideal choice for diverse customer needs, including R&D exploring recycled materials, QC ensuring material and product quality, and universities seeking compact and versatile research equipment. Despite its compact size, this mini conical extruder is compatible with a wide range of common recycled materials, including PET, LDPE, PP, Nylon, PLA and more.

New Mini Conical Extrusion Lines

Mini Conical Extruder

- Compact and space-saving design

- Cost-effective option

- Minimal material consumption

- Low power consumption

- Ease of operation

- Minimize shear stress and reduce material degradation

- Vacuum vent for volatile removal and pressure elimination (Lab. series)

Mini Conical Extruder

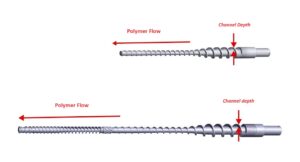

The high channel depth at the feed zone enhances material intake capacity, particularly beneficial for recycles materials, which are low-density plastics and high volume-to-mass ratio. Additionally, this deeper channel depth at the feed zone also helps prevent material bridging or clogging, ensuring smooth material flow.

Furthermore, the conical design offers versatility through two options: The low-shear screw and high-shear screw. The Low-shear screw is designed for heat-sensitive materials to minimize degradation, while the low-shear screw is suitable to handle blends and composite materials, ensuring efficient mixing and homogenization.

For the Lab series vented single-screw extruder, a unique conical screw design is offered to support degassing and moisture removal during extrusion. Additionally, both low-shear and high-shear configurations are also available for this series.